"The Family Company That Treats You Like One of Its Own"

Father Knows Best

Maynard Alderman Taught His Sons His Idea of How to Run a Business. It's a Good Thing the Boys Listened. by Jack Petree

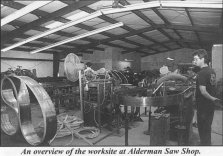

Alderman's Saw Shop was established when a nearby mill gave Maynard machine and allowed him to work out the price sharpening saws. He rented a garage and the company was underway, emphasizing bandsaw repair for nearby mills. Alderman, with help from his two young sons, soon established a reputation for quality and the business began to grow rapidly. In 1976, carbide saw repair was added to the mix. Garry, then just 15-years-old, was given primary responsibility for that end of the business. By 1978 the company had grown to the point where Maynard decided to leave his mill job to strike out on his own. A 30- by 60-foot metal building was erected and the shop regularly needed up to five employees. Alderman's Saw Shop, as constituted today, is an equal partnership between two brothers, Ronald and Garry Alderman, and their father, Maynard.

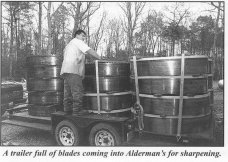

Today, as more and more sawmills are discovering the benefits of using an outside saw shop, the business continues to grow. The reasons range from a mill s inability to keep experienced employees on a long term basis to the high capital costs involved in equipment necessary to maintain modem saws. The primary reason, however, according to Ronald Alderman, is dependability. Until 1980, the shop mainly repaired blades from mills within a half-hour s drive from their plant. The decision was made that year to expand. Today the shop has 18 employees in two locations and services mills throughout the eastern seaboard, including facilities in Virginia, Maryland, Delaware, New York, and North Carolina. Maynard Alderman has retired, but Ronald points out that his father still comes in daily to "crack the whip and make sure we re doing things up to the standards he set for the shop."

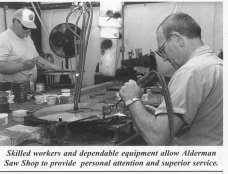

Garry succeeded his dad as president of the corporation and handles the circular saw side of the shop. Ronald specializes in the band end of the business, as well as the duties of vice-president. Alderman's Saw Shop has faced a number of efforts by national and international shops to come into the area and compete. It s a credit to the work effort of the entire Alderman team that the company is still used as the supplier and repairer of choice by some of the region s most advanced mills. According to Ronald, the confidence long-time customers have in the shop is rooted primarily in the fact that he and his brother still keep a hands on approach to the business. "We still work in the shop on a daily basis, so we know what is going on, how the blades are being repaired, and what the level of quality is," he says. "We don t sit in an office, watching others do the work. We are out there in the shop a good part of the time working on the blades ourselves. That helps us stay on top of our shop and make certain our customer is getting the best we have to give." The Aldermen also try to maintain a close working relationship with the mills they service. "If a mill is having trouble with its process, we try to work with it to find out what s wrong," Ronald says. "We feel as though we are, in a way, partners with the mills we serve. Our job is to help our customer maximize its production. We re part of the team. If things aren t working right, we will go out to the mill to see if we can discover what may be the problem. We sometimes make mistakes on a blade. We accept that. But if a mill is consistently having a problem, we know it isn t our blades.

Ronald says one of the primary reasons mills have gone from maintaining their own file rooms to utilizing a shop like his is reliability. "Filing is kind of a dying art," he says. "It s hard to find good filers, and when they are good, they tend to move around a lot. That puts the mill at the mercy of the fileroom. One person leaving can shut you down. By providing a reliable alternative, we allow the mill owner to control his own fate rather than have it in the hands of one employee."

Kirby Well of J.V. Well s in Sharptown, MD agrees that reliability is an essential part of the service Alderman's offers his mill. "We got tired of trying to hire qualified filers," he says. "With Alderman's, we know we have reliability. That is very important to a mill like ours." There are other reasons for outsourcing blade work to Alderman, Well says. "They have always done good work for us. We know we re going to get the quality we need. By using them, we don t have to constantly try to upgrade equipment. That saves us money and untold man hours. They have also been flexible. We have found it best to have a person on-site for our bandsaw work. They provide a man who works in our mill but is employed by them. It s worked out to be a good arrangement for us and we re very happy with them." Staying on top of all the changes that have come to the industry has been a challenge, Garry says. Equipment changes have meant capital investment and changes in technique have meant taking special care to assure that learning is an ongoing process.

On the learning side, Garry is careful to maintain communications with a wide variety of people in the industry. "News about new techniques travels by word-of-mouth in this industry," he says. "A lot of what s new is pioneered in Oregon and then works its way east. By keeping in touch with people in the industry we can make sure we re utilizing the new technologies as soon as they come available."

Garry says a real asset for his shop has been a periodic newsletter produced by Armstrong. "They have material from experts all over the world7 he says. "We ll read about something new, and if it seems as though it might make us better, we ll try it." Alderman's Saw Shop has been successful for 25 years. More than anything else, the brothers say, it s due to a philosophy passed down by their father and still in place at the shop: Always put the customer first. "If you treat the customer the way you would want to be treated, you can t go wrong," Ronald says, expressing his dad s way of doing business. "We re confident we will continue to be successful as we never forget that." Reprint premission by Industrial Reporting, Inc. © 1998 | |||||||||

Alderman's Saw Shop, PO Box 1205, Warsaw, VA 22572 804-333-4895 info@aldermanssawshop.com | |||||||||